In a rapidly industrializing country like India, ensuring the utmost quality in electrical systems within industrial facilities is not just a preference; it’s an absolute necessity. Electrical Quality Control Testing plays a pivotal role in maintaining the smooth operation, safety, and efficiency of these facilities. This comprehensive guide delves into the significance of Electrical Quality Control Testing for industrial facilities in India.

The Power of Quality Control

Unveiling the Backbone of Industry

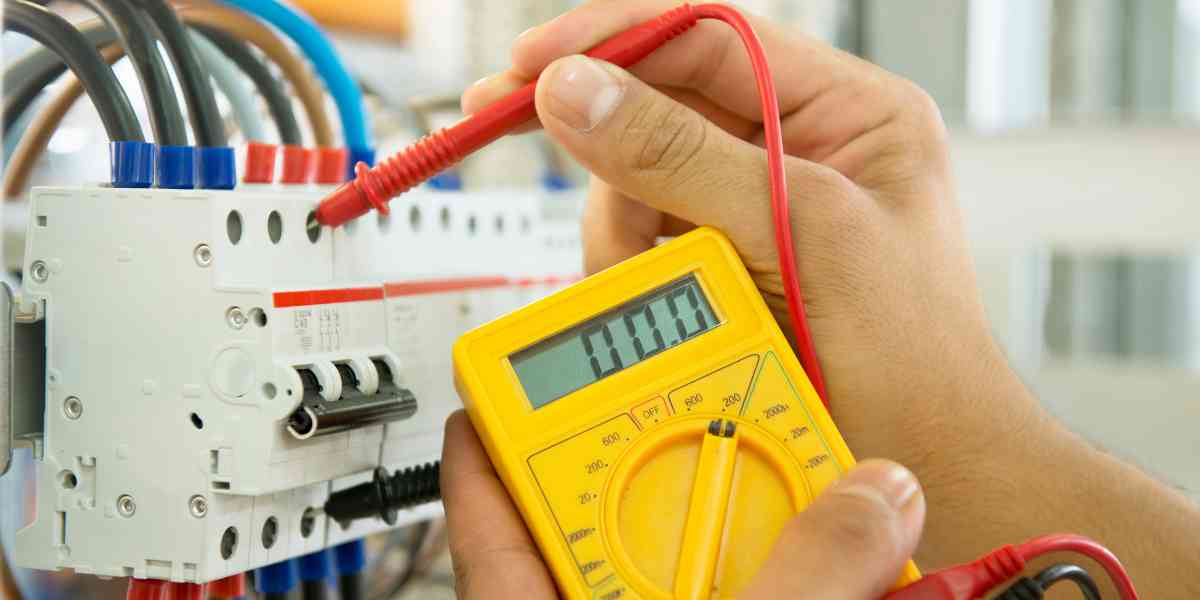

In the heart of every industrial facility in India lies a complex network of electrical systems, responsible for powering machinery, lighting, and essential operations. The uninterrupted and reliable flow of electricity is critical for ensuring manufacturing efficiency, employee safety, and product quality. Any disruption in power can result in costly downtime and significant financial losses.

Ensuring Safety and Reliability

Electrical accidents and equipment failures can have catastrophic consequences. Safety is a paramount concern in any industrial setting, and ensuring electrical system reliability is an essential component of this. Regular Electrical Quality Control Testing can detect potential hazards, prevent accidents, and safeguard the lives of workers.

The Indian Industrial Landscape

A Diverse and Thriving Sector

India’s industrial landscape is incredibly diverse, encompassing various sectors, from automotive and textiles to pharmaceuticals and energy production. Each sector has its unique electrical requirements and challenges. Effective Quality Control Testing adapts to these specific needs, ensuring that every industrial facility operates at its best.

Meeting Growing Energy Demands

As India’s population and economy continue to grow, so does the demand for electrical power. Industrial facilities must not only meet current energy requirements but also plan for future expansion. Quality Control Testing helps identify areas where energy efficiency can be improved, reducing the environmental impact and operating costs.

Regulations and Compliance

The Legal Imperatives

Compliance with safety and quality standards is a non-negotiable aspect of industrial operations. Indian regulatory bodies, such as the Bureau of Indian Standards (BIS) and the Central Electricity Authority (CEA), set stringent guidelines for electrical systems. Quality Control Testing ensures that industrial facilities meet these standards, avoiding potential fines and legal issues.

Benefits of Electrical Quality Control Testing

Maximizing Efficiency

Quality Control Testing optimizes electrical systems, identifying inefficiencies and areas for improvement. By addressing these issues, industrial facilities can reduce energy consumption and enhance productivity, ultimately leading to cost savings.

Preventing Costly Downtime

Equipment failures and power interruptions can lead to costly downtime. Quality Control Testing detects potential issues before they become major problems, minimizing disruptions and production losses.

Safety First

The safety of employees is a top priority. Quality Control Testing helps identify and rectify potential electrical hazards, ensuring a secure working environment.

The Future of Electrical Quality Control Testing

Embracing Technology

Advancements in technology, such as IoT-based monitoring and predictive maintenance, are revolutionizing the field of Quality Control Testing. These innovations allow for real-time monitoring of electrical systems, enabling proactive maintenance and reducing the risk of unexpected failures.

Conclusion

In the vast and varied industrial landscape of India, Electrical Quality Control Testing is not merely an option; it’s a prerequisite for safe, efficient, and productive operations. By adhering to rigorous testing standards and embracing technological advancements, industrial facilities can ensure a reliable supply of electricity, enhance safety, and drive productivity. Quality Control Testing is the key to unlocking the full potential of India’s industrial future.