Introduction

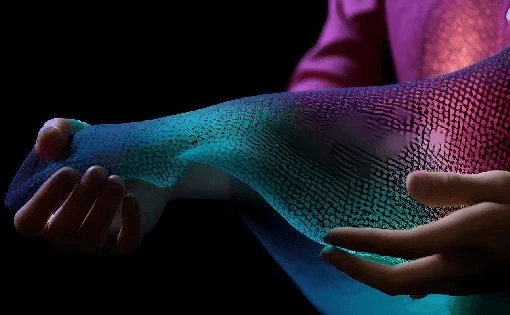

Functional textiles are a specialized category of textiles that are designed to provide specific functionalities beyond their traditional aesthetic and comfort purposes. These textiles are engineered to possess unique properties that enhance their performance and make them suitable for various applications in different industries.

Functional Textile Testing

Before functional textiles can be used in practical applications, they undergo rigorous testing to ensure that they meet the required standards and fulfill their intended functionalities. Here are some of the key tests conducted on functional textiles:

1. Waterproof and Moisture Permeability Testing

This test measures the ability of a textile to repel water and prevent its penetration. It also assesses the fabric’s ability to allow moisture vapor to pass through, ensuring comfort and breathability.

2. Performance Testing

Functional textiles designed to prevent static electricity buildup undergo antistatic performance testing. This test evaluates the fabric’s ability to dissipate static charges and minimize the risk of electrostatic discharge.

3. Moisture Absorption and Quick Drying Testing

Textiles that aim to absorb moisture and dry quickly are tested for their ability to absorb and release moisture efficiently. This test ensures that the fabric remains comfortable and dry, even during intense physical activities.

4. Thermal Insulation Performance Testing

Functional textiles intended for thermal insulation undergo testing to measure their ability to retain body heat and provide warmth. This test is crucial for textiles used in cold weather or outdoor activities.

5. Oil Repellent Performance Testing

Textiles that need to repel oils and other hydrophobic substances undergo oil-repellent performance testing. This test evaluates the fabric’s ability to resist staining and maintain its appearance and functionality.

6. Easy Stain Removal Performance Testing

Functional textiles that claim to have easy stain removal properties are tested to assess their ability to release stains and maintain their original appearance after cleaning. This test ensures that the fabric remains durable and easy to maintain.

Preparation of Functional Textiles and Their Production Status Quo

The preparation of functional textiles involves the incorporation of specialized materials or treatments during the manufacturing process. These materials or treatments are responsible for imparting the desired functionalities to the textile.

The production status quo of functional textiles has seen significant advancements in recent years. Manufacturers are continuously researching and developing new technologies and materials to enhance the performance and range of functionalities offered by these textiles.

Progress in Functional Textiles

The field of functional textiles has witnessed remarkable progress in terms of both innovation and market demand. The increasing awareness of the benefits offered by functional textiles has led to their widespread adoption in various industries such as sports, healthcare, and outdoor apparel.

New developments in functional textile technologies include the integration of smart textiles, which can monitor vital signs, regulate body temperature, and provide interactive features. These advancements open up new possibilities for the application of functional textiles in areas such as wearable technology and medical textiles.

Conclusion

Functional textiles play a crucial role in various industries, offering enhanced performance and functionality compared to traditional textiles. Through rigorous testing and continuous advancements in production techniques, functional textiles have become an integral part of our modern lifestyle. As technology continues to evolve, we can expect even more exciting developments in the field of functional textiles in the future.