In the dynamic and diverse world of the textile industry, the pursuit of product safety, regulatory compliance, and quality standards stands as an imperative. At the heart of this commitment lies chemical testing, an indispensable practice that not only upholds product quality but also ensures adherence to stringent industry regulations. This comprehensive guide takes you on a journey through the intricacies of textile chemical testing, covering everything from testing standards and regulations to the vital aspects of sample collection, preparation, and the various test methods employed.

Introduction

In an industry where innovation meets consumer expectations, textile chemical testing plays a pivotal role. It is the key to ensuring that textiles not only meet quality standards but also comply with regulations, addressing concerns related to safety, environmental impact, and labeling.

Testing Standards and Regulations

The textile industry operates within a framework of testing standards and regulations, each designed to guarantee the safety, quality, and compliance of textile products. Oeko-Tex® Standard 100, REACH, CPSIA, ISO 17025, ASTM International, and AATCC are among the prominent standards shaping the industry. Compliance with these standards not only ensures the safety of textile products but also provides a competitive edge by demonstrating a commitment to quality.

Sample Collection and Preparation

The foundation of accurate chemical testing lies in the meticulous collection and preparation of samples. Random sampling, appropriate sample sizes, and thorough documentation are crucial elements in this process. The significance of proper sample collection and preparation cannot be overstated, as it ensures representative samples that accurately reflect the entire batch.

Test Methods for Chemical Analysis

Chemical analysis in the textile industry involves a range of test methods addressing various aspects of textile composition and performance. From fiber identification to colorfastness testing, pH measurement, formaldehyde content, heavy metal testing, azo dye testing, tensile strength testing, dimensional stability testing, and abrasion resistance testing, each method serves a unique purpose in evaluating different characteristics of textiles.

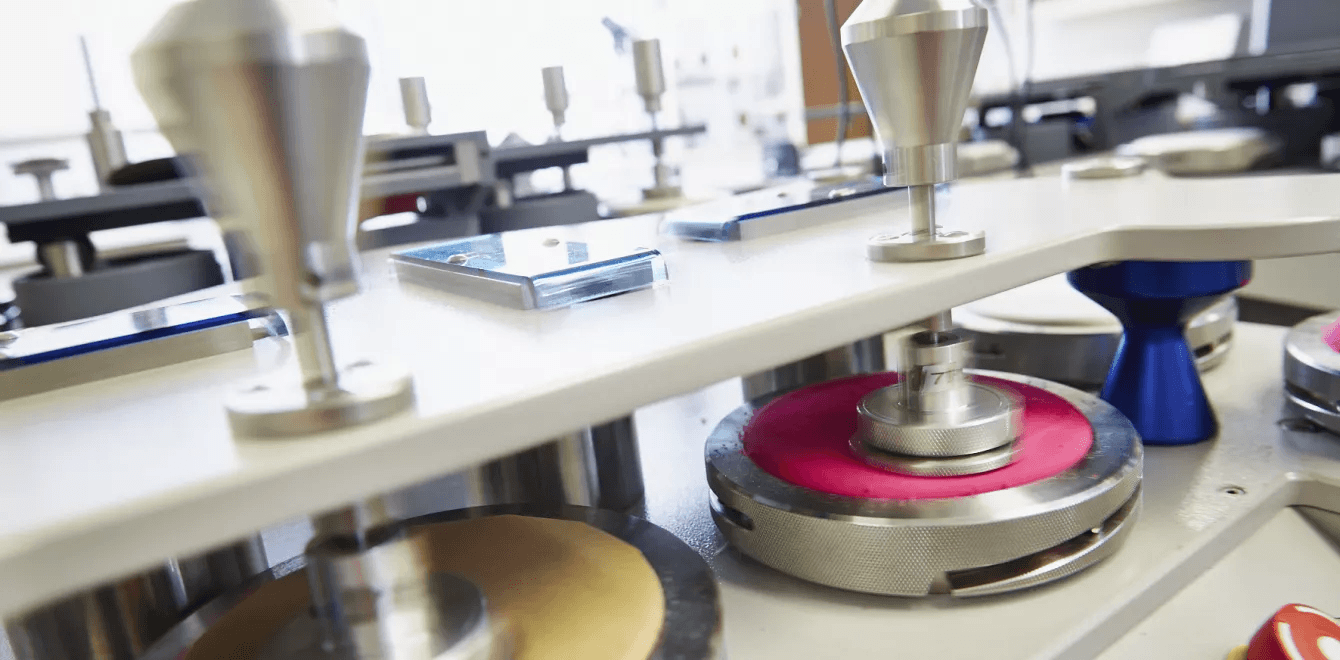

Laboratory Equipment and Instrumentation

The precision and accuracy of textile chemical testing heavily rely on sophisticated laboratory equipment and instrumentation. Spectrophotometers, Gas Chromatographs (GC), pH meters, Atomic Absorption Spectrometers (AAS), and other relevant instruments play a crucial role in assessing textile material composition, safety, and quality.

Test Result Reporting

Generating accurate and informative test reports is essential in conveying the results of various analyses. Test reports include units of measurement, detection limits, thresholds and guidelines, detailed methodology, and sample identification. Clear and comprehensive reporting ensures transparency and facilitates informed decision-making.

Interpretation of Test Results

Interpreting test results involves comparing them to established thresholds or guidelines to determine compliance. Non-compliance may trigger corrective actions, emphasizing the importance of consistent testing and interpretation for consumer safety and confidence.

Quality Control and Assurance

Quality control and assurance are the pillars of textile chemical testing, guaranteeing precise and reliable results while upholding safety and quality standards. Reference materials, proficiency testing, adherence to laboratory accreditation standards, and the overall benefits of quality control and assurance contribute to maintaining industry credibility and excellence.

Conclusion

In conclusion, chemical testing in the textile industry is not just a requirement; it is a commitment to excellence. From adhering to rigorous testing standards and regulations to meticulous sample collection, and preparation, and employing advanced test methods, the textile industry is dedicated to delivering products that meet the highest standards of safety, quality, and performance. Embracing quality control and assurance practices ensures not only regulatory compliance but also fosters trust, reliability, and continuous improvement. As consumers demand more from their textiles, the industry responds with a commitment to innovation, sustainability, and the assurance that every piece of fabric meets the highest standards of safety and quality.