We offer metal & alloys testing services

Our Metal & Alloys Testing services offer comprehensive testing and analysis of the physical and chemical properties of metals and alloys. We use state-of-the-art equipment and technology to ensure accurate and reliable results, providing our clients with the information they need to make informed decisions about their products.

Metal and alloys testing is an important aspect of ensuring the quality and safety of products made from these materials. At our testing facility, we offer a comprehensive range of metal and alloys testing services to help our clients meet their quality control needs and regulatory requirements.

Our metal and alloys testing services cover a wide range of materials, including steel, aluminum, copper, brass, titanium, and nickel alloys. We use state-of-the-art equipment and technology to provide accurate and reliable test results, ensuring that our clients have the information they need to make informed decisions about their products.

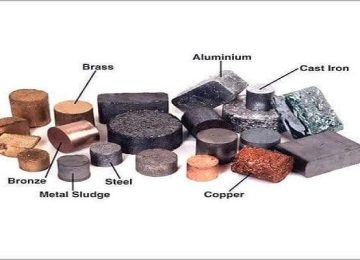

What Types of Metals & Alloys We test

- Aluminum testing

- Brass testing

- Bronze testing

- Cast iron testing

- Copper testing

- Gold testing

- Inconel testing

- Lead testing

- Zinc testing

- Titanium testing

- Magnesium testing

- Monel testing

- Nickel testing

- Palladium testing

- Platinum testing

- Silver testing

- Stainless steel testing

- Steel testing

- Tin testing

Testing Parameters We offer

At our testing facility, we ensure the highest standards of quality and accuracy in all our testing services. We understand that accurate and reliable test results are essential to our clients’ success, and we are committed to providing timely and comprehensive testing services to meet their needs.

Diameter of Aluminum Wire | IS 398(Part-1), Cl:12.2 |

Breaking Load of Individual Aluminum Wire | IS 398(Part-1), Cl:12.3 |

Wrapping for Aluminum Wire | IS 398(Part-1), Cl:12.4 |

Conductor Resistance | IS 398(Part-1), Cl:12.5 |

Lay Ratio | IS 398(Part-1), Cl:12.6 |

Diameter of individual Aluminum & Steel wire | IS 10810(Pt-2) Cl:13.2 |

Breaking Load of Individual Al Wire& Steel wire | IS 398 (Part-2) Cl: 13.3 |

Ductility /Elongation | IS 398 (Part-2),Cl: 13.4 |

Wrapping | IS 398 (Part-2), Cl: 13.5 |

Surface Condition | IS 398 (Part-2), Cl: 13.9 |

Ultimate Breaking Load on Stranded Conductor | IS 398 (Part-2) ,Cl: 13.10 |

Stress Strain | IS 398 (Part-2), Cl: 13.11 |

Lay Ratio | IS 398 (Part-2),Cl: 13.8 |

Mass of Zinc Coating | IS 398 (Part-2),Cl: 13.7 |

Conductor Resistance | IS 398 (Part-2),Cl: 13.6 |